Inspection Tours Support System

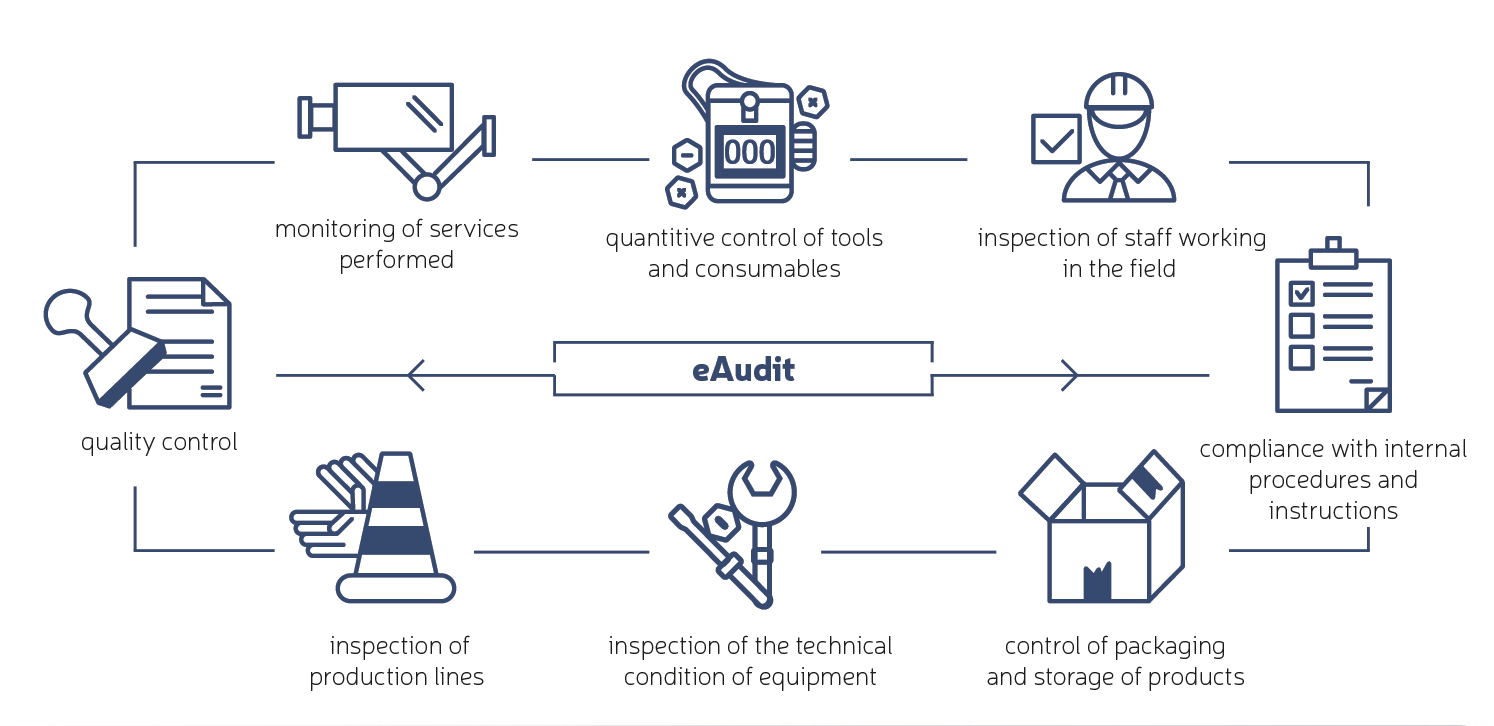

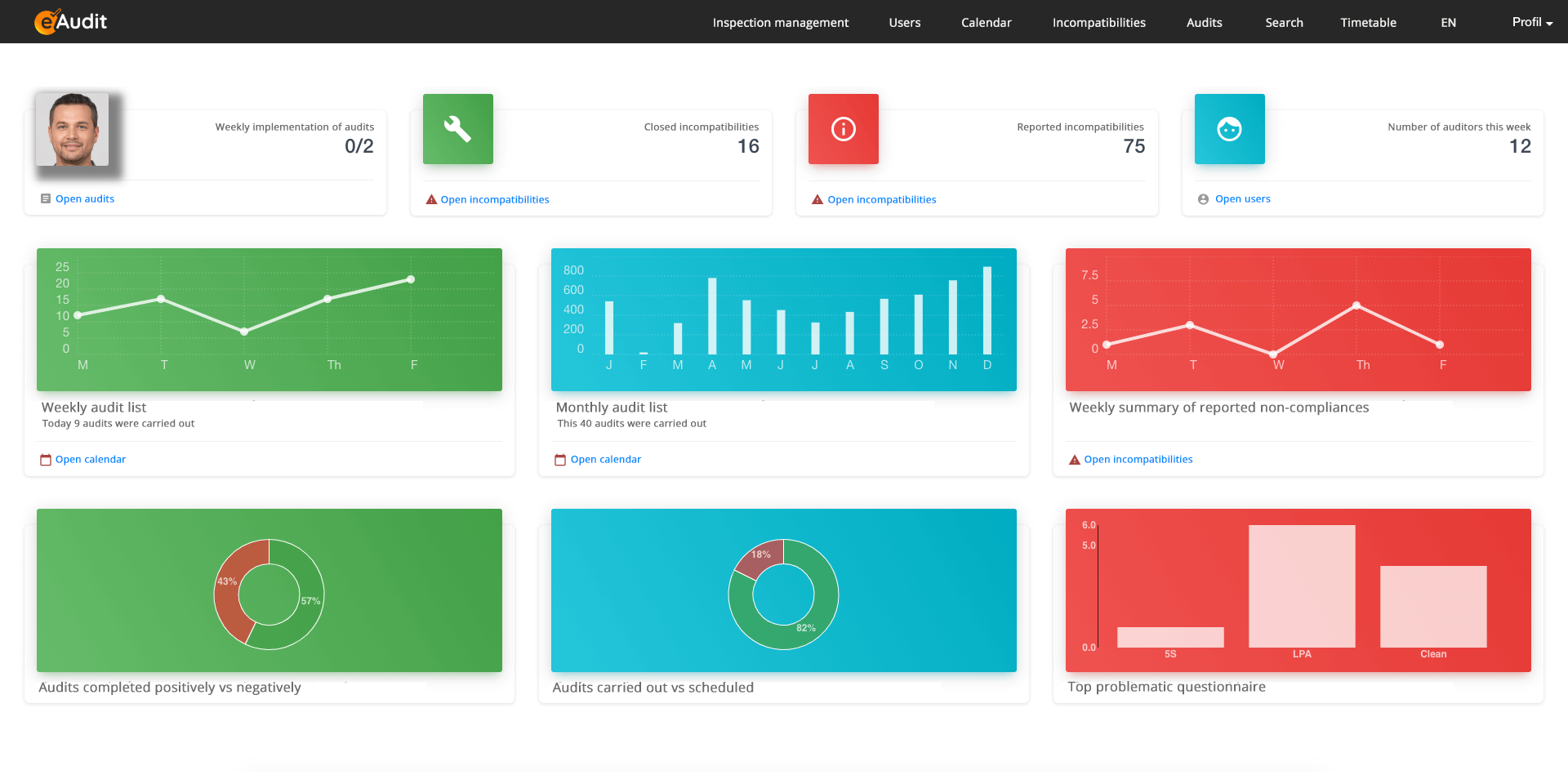

eAudit – The Inspection Tours Support System is a user-friendly application enabling to register and to report data collected from surveys. The scope of collected information is defined by a user when configuring the system.

How eAudit Works

The functionality of the application of this type comprises:

Data recording

on mobile devices in the form of fill in the questionnaire/survey.

Identification

of the actual amount of conducted tours, as well as areas / locations covered by the inspection.

Ability to compare

current and historical data indicating trends resulting from the inspection tours.

The system consists of the following modules:

Application for mobile devices

for a person carrying out an inspection.

Central application

collecting data and making reports available.

LPA

Layered Process Audit

Applied technologies:

Cross-platform

technology used to create a mobile application (based on Open Source Framework Apache Cordova). Thanks to that technology once built application can be used on many operating systems (Android, Windows Phone, iOS, Windows and other).

JEE technology

Java technology was used to implement a core part of the system (services, application, reports etc.)

Microsoft Windows Server

or any Linux distribution, a dedicated database PostgreSQL (possibility to use a different database, eg. Microsoft SQL Server).

Free Consultation

User-friendly application

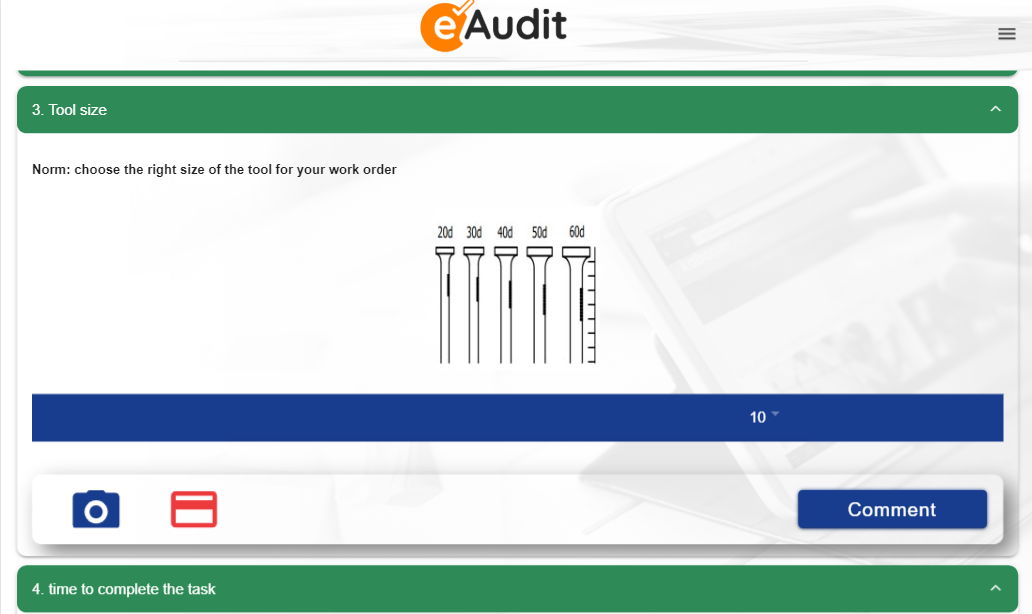

The application for mobile devices:

Data about a current state of checkpoints are recorded directly on mobile devices (e.g. tablets) working in a wireless network or offline. The application allows employees in ergonomic and easy way to fill in the survey according to an approved scheme or inspection schedule.

The central application:

The central application is available through the web browser and enables to generate aggregate reports based on data collected in surveys. All available reports can be exported to a .xls files.

Sample reports:

An incompatibilities report

the report contains information about all the incompatibilities that occurred during inspection.

A report from inspection tours

the report presents the tours within a defined period of time.

Graphical report

the report presents a graphical trends in a given period of time.

Free Consultation

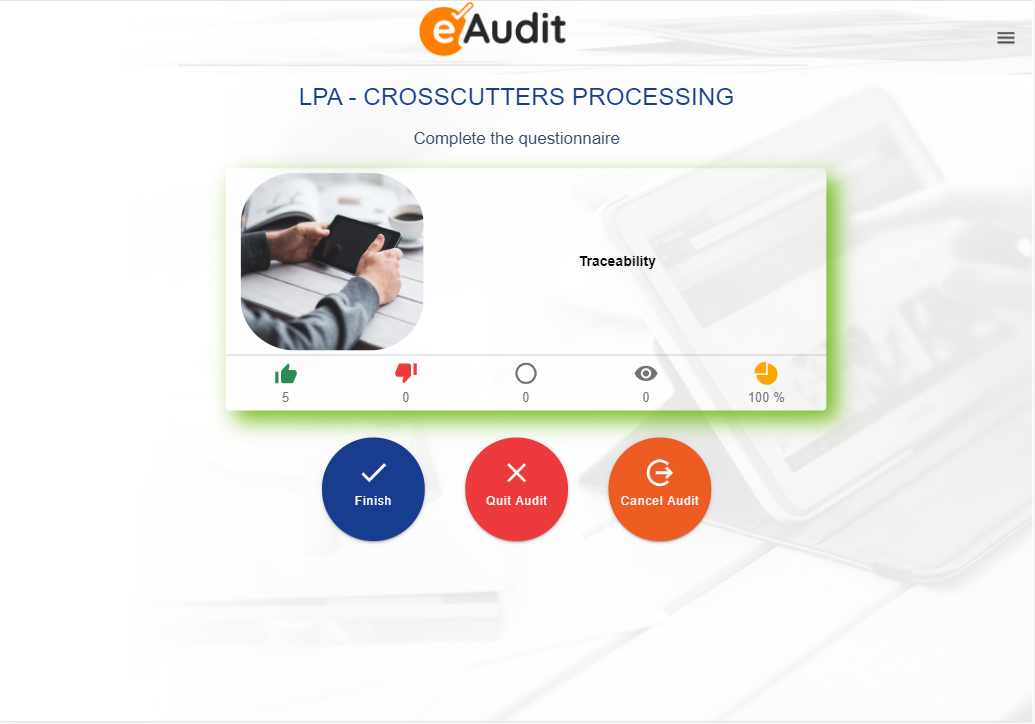

LPA – Layerd Process Audit

eAudit support LPA

LPA is a layered audit process. It is a multi level methodology of a process evaluation for the internal production, which is implemented by a different of staff from a few levels of management.

Ehnance the quality of Production

The applyied layerd process audit allow production avoid from simple malfunctions of employees’ work, equipment shortages and quick capture of out of date.

Complementary product

eProduction

System production flow data is recorded directly on the production hall

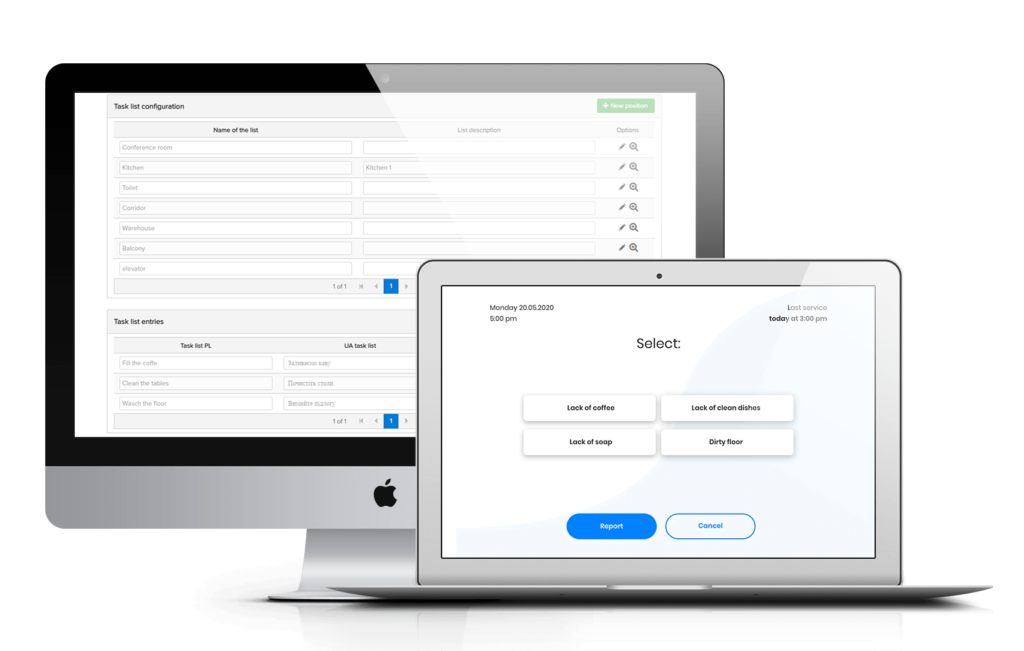

eCare

The application allows to minimize both information exchange through e-mails and paper documents flow

eClean

The system will help keep your organisation clean on large surfaces.

Key eAudit implementation benefits

Leaving the paper method of registration and data analysis aside and introducing electronic devices significantly increases inspection efficiency and in fact allows for improvements implementation on time.

Production quality improvement and security increase

Control of the specific points for every areas, for every production line, by comparing the actual state with established standards, allows us to constantly increase production quality and eliminate errors

Losses reduction

Thanks to real time data analysis responsible people can instantly react for every irregularity encountered by checkpoints which result in to e.g. by implementing corrective measures by its own staff or by outside companies.

Faster and more effective decision-making

Spotting a problematic checkpoint in a production line allows improvement and increase of process efficiency. Real time analysis of current data correlated with historical data provides indicating an inefficient link and allows proper reaction to resolve a problem in the shortest time.

Effort reduction

Thanks to usage of mobile devices and the Inspection Tours Support System, completion of surveys takes place directly on the production floor or at the point of service. Time needed for data registration from surveys is shortened which allows fast reaction in case of spotted irregularity. The analytical data are available for the management responsible for the quality assessment.

Support for the planning

The system supports the creation of inspection calendars (plans) for both individual employees, as well as areas / locations.

Indisputability of collected data

During executed inspection there is mobile device functionality to execute photo documentation of spotted irregularity or deviation. Photo documentation constitutes a proof of existed irregularity which is very hard to discredit.

eAudit

Successful Launch

Velux

NB Polska Sp. z o. o. (VELUX group) – a company from manufacturing sector with over 70 years of experience. Factories located in Poland produce windows both for domestic and European market (3/4 of manufacturing).

Client’s Needs

The awareness of changeable market conditions and increasing competition has created a need of implementing innovative solution that allows agile collection and processing of the data from manufacturing.

This approach was to chosen to ensure easy access to data and their rapid analysis for controlling production process needs and hence a possibility of quick response in case of deviation from an established plan.

moNThs

Team Members

Trusted by Leaders

We'd love to talk,

drop us a line!

Exence S.A.

Bielany Wrocławskie

ul. Szwedzka 5,

55-040 Kobierzyce, PL

tel: +48 71 782 06 00

email: moc.ecnexe@eciffo

Office Opening Hours

M-F: 8am - 5pm (CET)

S-S: Closed