Maintain large scale cleanliness systematically across your entire organisation

Companies that want to increase their competitiveness and efficiency are introducing new electronic methods of work management, performance control and acceptance of completed work, as well as broad process optimisation.

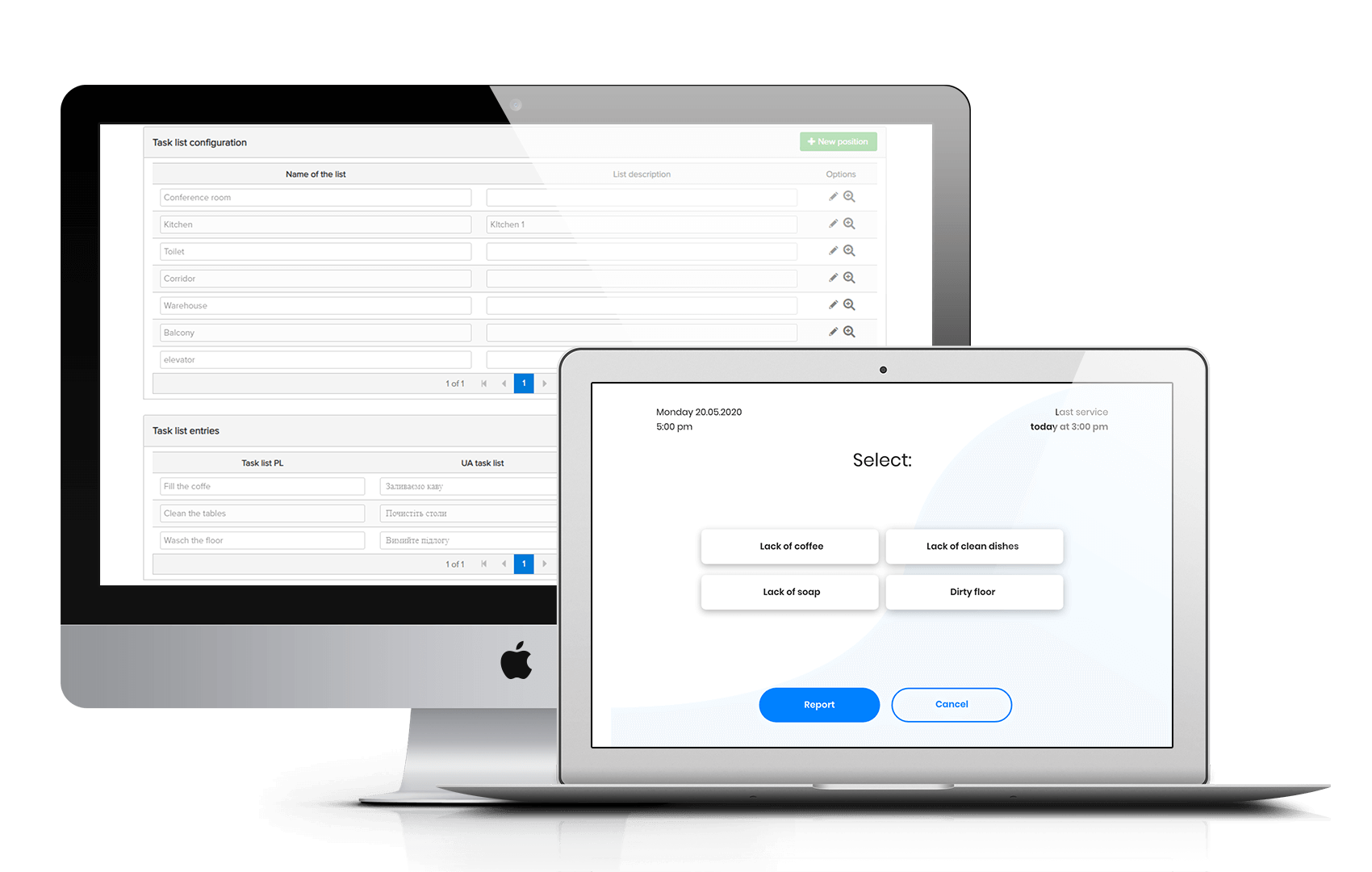

How eClean Works

Key functions of eClean:

Report of Cleaniliess

full control over all properties and objects.

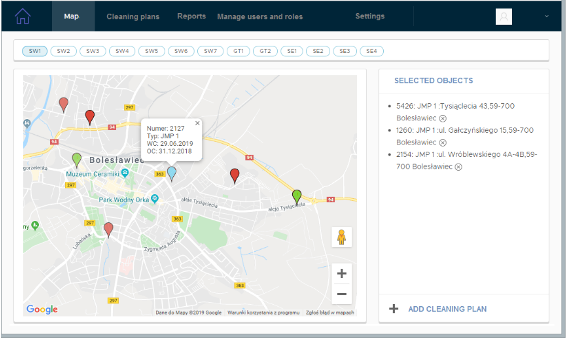

Geological Coordinates

cleaning directly from the map view.

Doorcounting sensor

count the number of people using the room.

The system consists of the following modules:

Application for mobile devices

easy to find and information on smartphone or tablet.

IoT Technology

NFC – machine sticker, we apply a tag and get data on the phone.

Customer speaking

A modul via tablet to evaluate a customer contentment.

Planning and acceptance module

Help keep the area clean

The planning module allows you to create work plans for cleaning crews and an optimal indication of the dates of cleaning facilities

All the information needed in one place

The system maintains a full list of objects subject to cleaning along with basic object data (number, type of object, address, contact details of the supervisor, cleaning history, planned repairs, etc.).

An ingenious planning

Based on detailed data about places and objects combined with the cleaning history recorded in the system, special algorithms allow you to schedule cleaning dates and create work plans with the exact dates for the objects and areas along with the team responsible for carrying out the work. Put your work effort in the places it’s needed most.

Get Free Consultation

Smart Cleaning plan via map and NFC integrated

System supports also Maps vie and automatically determine the geographical coordinates (LAT, LON) of an object based on the address data of the object, which allows you to show the objects on the map and manage cleaning directly from the map view.

The map view shows the exact location of the objects and the corresponding color indicates the objects that are already included in the cleaning plan, the other color the objects for which the plan should be prepared and the other color the objects that do not require any action at the moment.

The system allows for cyclical work planning by preparing cleaning plans. The plans are prepared for a specific period of time, e.g. one or few months, and contain a list of objects that were planned to be cleaned in a given period.

NFC tags are designed as stickers that can be of different sizes and can be graphically designed in any way. These stickers or labels can be affixed in the rooms and thus identify the room in the employee’s application. This NFC tag will encode the room code and the app will allow the app to scan and automatically set the app context and survey for your room.

Cleaning Plan:

Planning, verification and reporting...

Cleaning plan is first generated by the planner and then sent to the regional coordinators for approval. After approval of the regional coordinators, the plan can be sent for approval of the persons responsible for planning cleaning on the client’s side. These persons can submit comments on the plan in the form of comments, and thus the final list of facilities and cleaning dates in facilities are agreed.

In the system, it is possible to generate reports (Excel) with a work plan for cleaning teams as well as reports for coordinators or planners. After approval of the plan, the plan is also automatically sent to the audit and work status reporting system, which, based on the approved plan, generates surveys for cleaning crews, which will be supplemented according to the schedule during the implementation of the works.

Get Free Consultation

People counting system – footfall counter

The ability to track traffic and count the number of people entering/leaving the room can be very helpful in creating the optimal workflow of service workers, which can be determined by the number of people using the room.

The system counts the number of people in the room during certain hours and/or days, sending notifications when the number of people in the room exceeds set amounts. This allows you to generate reports and analyze the collected data in real time.

IoT – motion sensors

These sensors are able to respond to incoming persons and to periodically transmit this information to the database.

The easiest solution is to place motion sensors (PIR) that are used frequently in alarm systems or to control lighting.

In combination with a suitable transmission device (e.g. WIFI or GSM module), it is possible to send the central system the number of signals the sensor has recorded.

Complementary product

eProduction

System production flow data is recorded directly on the production hall

eCare

The application allows to minimize both information exchange through e-mails and paper documents flow

eAudit

The system will provide the ability to report the visit to the facility of contracted people.

Audit and work status reporting module

The audit and work status reporting module (called eAudit) allows for ongoing verification of the status of work carried out by cleaning teams.

Step 1

Scheduled and approved cleaning plans are sent as a work schedule to the eAudit system. System automatically generate surveys for each object along with the expected completion date of works in this facility.

The audit system is used to supervise the work of the teams and to thoroughly verify the effects of the team’s work on each facility.

Step 2

The team leader log in to the application, in which he receives a list of objects on the start screen in which he should perform cleaning in the following days.

Before starting work on each object, the leader should launch a survey dedicated to the object and, along with the progress of work, report the implementation of individual stages of work.

Stages of work are reflected in the survey questions. After completing each of the stages of work on the object, the leader reports the status of implementation by selecting one of the possible answers to the question in the survey.

Step 3

Among the available response options (in addition to the basic answer: Done) there are also those that allow reporting problems during implementation or unavailability of areas in the facility. In addition to choosing the answer, you can add a comment and take a photo that documents the specific situation.

Both the answers given as well as comments and photos are registered in the system on an ongoing basis and can be verified in the work report.

Step 4

After finishing work and cleaning, complete the survey. The survey ends after correctly entering the PIN code that the store manager receives in an SMS message in which we inform in advance about the upcoming visit of the cleaning team.

Store supervisors receive cyclical SMS messages (e.g. one week ahead of schedule and two days before planned cleaning) with information about planned work. The message also includes a PIN that allows you to accept the survey and thus receive and approve the work carried out on the site.

Step 5

If the cleaning service is not performed or is incomplete in a given area, the question mark will be marked as “Not done” in the survey and an irregularity will be automatically generated (complaint) for the given area.

Then it is possible to manage irregularities in the Inspection Tour system and assign them to a specific team (person) and indicate the deadline for completing the complaint.

Step 6

Assigning irregularities to the team (person) and indicating the date results in generating a new survey in which the areas subject to complaint will appear. After removing the irregularities and completing the actions related to the complaint, the survey will mark the areas again as completed and the works (and surveys) must be accepted with the PIN code received by the facility supervisor.

All irregularities and complaints will be reported in a special list, which will be sent via email to regional managers and coordinators. The statements can be sent as a complete summary of the work or only if the cleaning did not take place (the team did not arrive, the store was not prepared) or if all the activities were not carried out or there are comments and complaints about the cleaning service.

In addition, a monthly report will be sent to selected users with all scheduled cleanings scheduled and their statuses. This report is the basis for financial settlements for services rendered.

Trusted by Leaders

MTiW Successful Launch

Südzucker Polska S.A.

Südzucker Polska S.A. registered office: ul. Muchoborska 6, Wrocław, Poland.

The company is part of the European Südzucker Group, the largest sugar producer in Europe. Over the past few years, the company has consolidated 22 sugar companies, which has allowed the company to modernize. Currently, Südzucker Polska S.A. produces sugar in five sugar production factories around Poland.

Client’s Needs

- Warehouses to be equipped with autonomous devices to measure temperature and humidity conditions;

- Automation of information collection about current conditions in warehouses;

- Reporting current conditions and sending notifications when conditions deviate from specified optimal temperature and humidity levels in warehouses;

- Quick access to current and historical data for persons responsible for storage.

moNThs

Team Members

We'd love to talk,

drop us a line!

Exence S.A.

Bielany Wrocławskie

ul. Szwedzka 5,

55-040 Kobierzyce, PL

tel: +48 71 782 06 00

email: moc.ecnexe@eciffo

Office Opening Hours

M-F: 8am - 5pm (CET)

S-S: Closed