The system collects, records and reports information directly from the production line. Users can specify the types of information collected during the initial configuration stage and later in the configuration settings. Thanks to this flexibility, it can be adapted to the client’s changing needs. The system is able to record and display a range of crucial information such as downtime, wear, workload, shortages, errors, services and other operations performed.

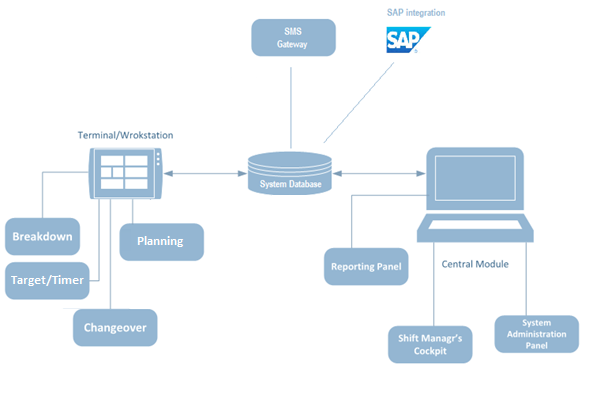

How eProduction Works

The system consists of the following modules:

Acquisition of data from production lines

Presentation of data in the production hall

Central module with web application

reporting, administration, data analysis, shift leader dashboard

Registration of employee activities

mobile application

Module can integrate with production machine controllers

The production line data acquisition module allows the integration of applications with production machine controllers

Examples of types of data collected:

Number of semi-finished /finished products produced

Production line breakdowns together with the reason for the breakdown

Machine downtime (including that related to maintenance and prevention)

Free Consultation

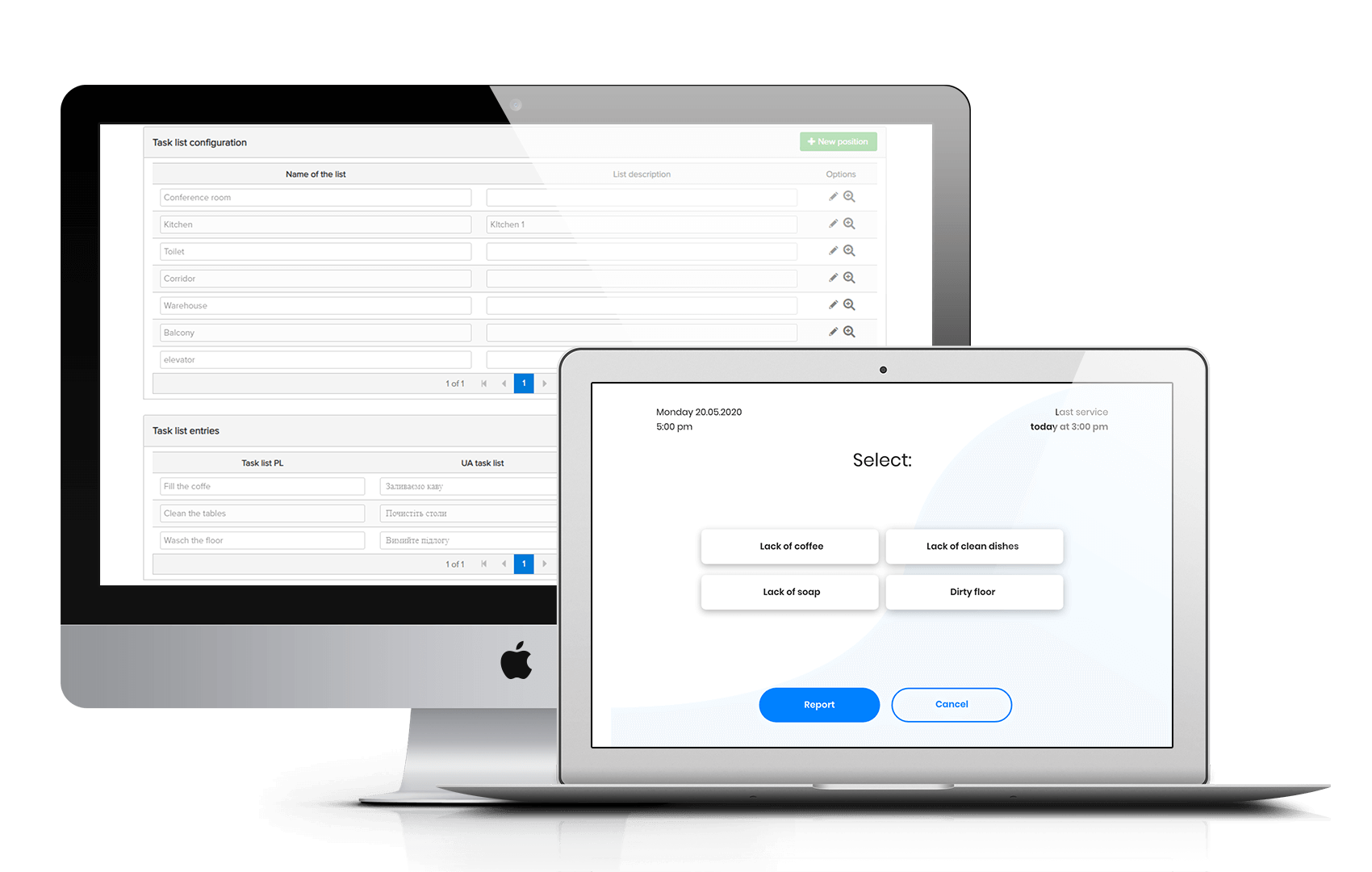

Registration of employee activities

Data on the progress of production are recorded directly from the production hall using touch terminals, additionally equipped with proximity card readers for employee identification. The goal is to track the production process, compare actual implementation with that planned and prepare data to help planning subsequent operations. The system enables production operators to enter current production data using simple, user-friendly forms on handy devices. The data is sent from these devices to the central system and central database via WiFi (or LAN).

The application installed on mobile devices is prepared in such a way that it is possible for machine operators to record data in an ergonomic, easy way. The system can be integrated with machine controllers in such a way that data is automatically received directly from the machines. In the central system all data, including the time parameters of each action and identification of the user taking a specific action, is recorded on an ongoing basis. In this way, it is possible to analyze and report important indicators and data from the production process as well as breakdowns and downtime, which is essential from the point of view of managing the organization of work and costs.

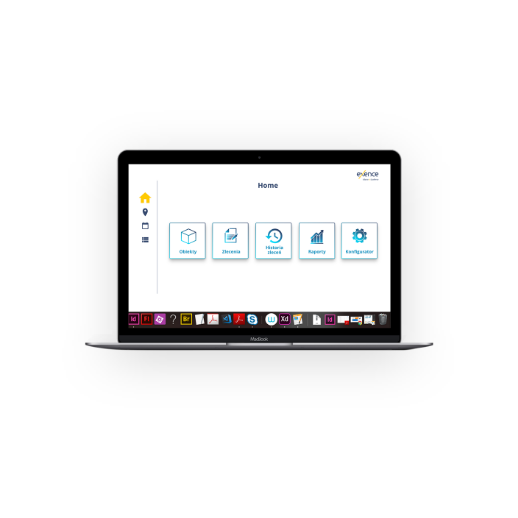

Central module with web application:

The system includes a web application whose parameters can be tailored to the individual needs of the client during the implementation process. The central module is divided into 3 functional areas:

System Administrator Panel

Shift Manager dashboard

Reporting panel

Free Consultation

Complementary product

eClean

The system will help keep your organisation clean on large surfaces.

eCare

The application allows to minimize both information exchange through e-mails and paper documents flow.

eAudit

The system will provide the ability to report the visit to the facility of contracted people.

Key benefits of eProduction

Discarding paper methods of data collection and analysis and replacing them with electronic devices significantly increases the efficiency of inspections and, in fact, allows for scheduled.

Paperless registration of production processes

By replacing paper documents with electronic equivalents, there is a significant reduction in the time required to register work by operators, which directly increases the efficiency of the production process. Data on the production process are available online for shift managers, production managers and management to analyse.

Monitoring of operators’ work

The system allows you to monitor the work of individual operators, shifts or shift managers.

Reporting options

Depending on the type of data recorded, very complex reports can be defined in the system and can be generated on demand. Thanks to this, the waiting time from the moment the report is requested to its production is just a few minutes. The system produces two types of reports: the first relates to reporting data from the current shift (directly viewable on monitors installed on the production lines), the second kind is available to authorized persons, in particular supervisors, and can analyse current and historical data to provide more detailed analysis.

Waste and loss reduction

Thanks to real-time data analysis, the shift manager can immediately respond to any irregularities in the production process, which result in situations such as a decrease in the quality of finished products. In such a situation, a manager may, for example, decide to suspend production the problem is solved. This reduces the amount of materials lost and media consumed.

Faster, more effective decision making

Finding an inefficient link in the production process allows you to streamline and increase the efficiency of the entire process. Only by analyzing production in real time can we effectively determine the inefficient link and model its improvement. In the production process, the individual components depend on each other – by raising the level of performance in one place, we can lose product quality or availability due to increased breakdowns or downtime.

Optimization of the production process

Optimizing the effectiveness of the manufacturing process requires performance to be measured and information collected on quality and availability. The correlation of these data allows you to determine the efficiency of the production process and strategies for its optimization.

eProduction Successful Launch

Voestalpine Rotec

The factory, producing parts for the needs of the automotive industry, is located in Komorniki near Środa Śląska, Poland. Its involvement in global supply chains requires efficient organization, timeliness and high quality of the manufactured goods.

Client’s Needs

The client required an innovative solution that would allow more efficient control over the production process and order fulfilment on all production lines. A great emphasis was placed on increasing productivity and the expansion of the plant was a great opportunity to optimize production processes so that they became more efficient, economical and modern.

moNThs

Team Members

Trusted by leaders

We'd love to talk,

drop us a line!

Exence S.A.

Bielany Wrocławskie

ul. Szwedzka 5,

55-040 Kobierzyce, PL

tel: +48 71 782 06 00

email: moc.ecnexe@eciffo

Office Opening Hours

M-F: 8am - 5pm (CET)

S-S: Closed