Voestalpine Rotec

An IT system for data collection and monitoring production.

The system enables data recording and reporting in real time, which improves analysis and visualization in the form of reports and dashboards.

- Launch: 3 months

- Client: Voestalpine Rotec

- Specialists: 4

About this Project

Client:

Voestalpine Rotec, a manufacturer of metal components for the automotive industry. Their factory is located in Komorniki near Środa Śląska, Poland. The factory produces metal elements for the needs of the international automotive industry. The global nature of its operations requires proper organization, timeliness and high quality products.

Solution:

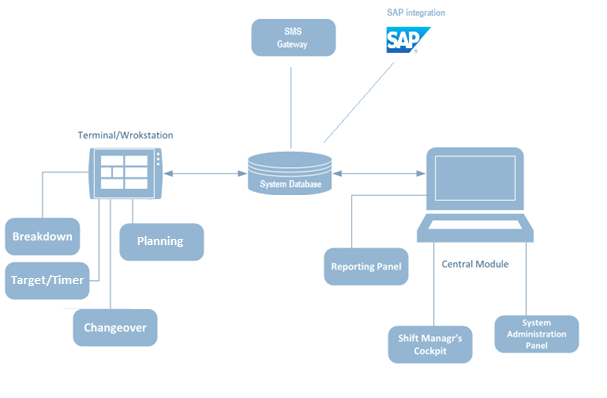

Implementation of the Electronic Production Data Collection and Monitoring System (called eProduction), whose main purpose is to collect data directly from operators’ stations using mobile devices. The data collected in real time are the basis for a variety of reports on including statuses and progress of orders, failures, retooling, tool changes and OEE indicators.

This approach ensures easy access to data and their efficient analysis, and thus the ability to react quickly in the event of any changes in production plans as well as management of planned and unplanned downtime.

Software and technology:

- .NET technology – Microsoft .NET technology has been used to implement the central part (services, application reports, etc.) and to prepare applications for mobile terminals.

- Microsoft Windows Server and Microsoft SQL Server database – the central part has been implemented on an environment with the Microsoft Windows Server operating system and the Microsoft SQL Server database.

Proven results

Registration

registration of current data in a central database directly from the production hall using mobile devices,

Monitoring

real-time monitoring of equipment and efficiency of production processes,

Calculating

automatic calculation of OEE indicators for machines and lines,

Report

reporting for any period and in any system (e.g. line, machine, product, change, employee)

Solution

The first stage of implementation was the pilot launch of the System. Mobile devices were configured, on which dedicated software for stations and operators was installed. The Central System was also implemented, and in it, stations, machines, products and all parameters needed for the proper operation of the System at Rotec were configured.

The central application is available through a web browser that allows users to generate reports on the data collected from checkpoints. Reports can be exported in .xls, or .pdf forms.

The roll out of the System was supported by Exence consultants, who in the first stage helped employees learn about the System and quickly responded to any questions. In the next stage, the System was made available to operators who were to enter specific data and events on the terminals (shift selection, start and end of work, entering the number of products produced during the shift, registration of start and end of changeovers and failures, change of tool (cutting knife) ). The data collected in this way is saved on an ongoing basis in the database and used for reporting and analysis of current and historical data.

Get Free Consultation

Related Projects

Velux

Shop Floor Data Collecting System has been created and has become the central database gathering data concerning damages from production, failures, downtimes and information about rotation of employees between positions.

MTiW

Temperature and humidity measurement and monitoring system. The solution is based on Microsoft technology, GSM / GPRS transmission and LAB-EL devices. The solution has been implemented in 8 warehouse facilities.

ePresenter

Implementation of a content publication management system enabling images, videos and any other information to be broadcasted on industrial monitors located in production halls.

We'd love to talk,

drop us a line!

Exence S.A.

Bielany Wrocławskie

ul. Szwedzka 5,

55-040 Kobierzyce, PL

tel: +48 71 782 06 00

email: moc.ecnexe@eciffo

Office Opening Hours

M-F: 8am - 5pm (CET)

S-S: Closed